96%Cotton4%Conductive Carbon Fiber 0.5cm/0.8cm Stripe Anti

Description

Basic Info.

| Model NO. | SHTX-V-C02 |

| Knitting Technics | Weft |

| Physical Feature | High Strength |

| Fiber Cross Section | GOAT |

| Transport Package | Plastic Bags |

| Specification | 30S |

| Origin | China |

| Production Capacity | 1000000ton/Year |

Product Description

96%Cotton4%Conductive Carbon Fiber 0.5CM/0.8CM Stripe Anti-static ESD Single Cotton Jersey Fabric For T Shirts Overalls | |

No. | SHTX-V-P17 |

Material | 96%COTTON4%CONDUCTIVE CARBON FIBER |

Weight |

160GSM |

Width | 57/58 Inches |

MOQ | 1000 M |

Delivery Time | 7 Days |

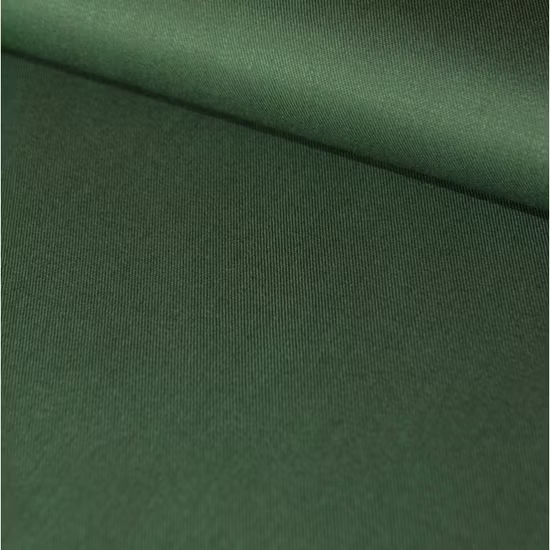

Product images

96%Cotton4%Conductive Carbon Fiber 0.5CM/0.8CM Stripe Anti-static ESD Single Cotton Jersey Fabric For T Shirts Overalls

Our Advatage

96%Cotton4%Conductive Carbon Fiber 0.5CM/0.8CM Stripe Anti-static ESD Single Cotton Jersey Fabric For T Shirts Overalls

1.Quality and Competitive Price

We Have Our Own Weaving Factory, Dyeing Factory, Coating Factory and Bonding Factory.

All of Our Factories Build Up the Perfect Production System to Control the Quality.

Our Price Is Very Competive as Supported by Our Factories.

2.Experience

We Have Engaged in the Fabric Line for 20 Years, So We Have An Experience Sales

Team Who Know the Market Very Well and Support Customers to Develop Many Projects.

Our Experienced Quality Controlled Team and System Insure Our Company Do Long

Term Business with Customer.

3,Responsible

Responsibility Supported Our Company Be Bigger. We Take Responsibility of The Quality of Our Fabric. If Customer Is Not Satisfy Our Quality, Customer Can Return back the Fabric, We Will Take Responsible for Customers' Loss.

4,Business Rules

1)Be Honest for Customers,Always Be Together with Customers.

2)Hard Working and Take Serious Attitude for Any of Custmoers' Order,No Matter It Is Big or Small Quantity.

3)Following Strictly of Customers' Required Standard.

4)Keeping Satisfied Quality of Fabric by Customers and Price Lower.

Production Process

1,Weaving Of Raw Gray Fabric

Using the Advanced Machine to Keep the Good Quality of Raw Material,

Worker Are All With Experienced Persons.

2,Inspect of Raw Gray Fabric

Inspected By Experienced Workers, Keep The Perfect Raw Gray Fabric As "A" Grade, Keep The Defective Raw Gray Fabric As "B" Grade, "B" Grade Fabric Is Not Allowed

To Be Used Without Customer's Permission.

3,Dyeing Of Raw Gray Fabric

Dyed By Own Experienced Workers In Our Own Dyeing Factory To Keep the Color Perfectly, Keep The Color Fastness Perfectly,Keep The Dyeing Fabric Is Eco-Friendly.

4,Treatment of Dyed Fabric

Inspected the Dyed Fabric by Experienced Person, Reject the Defective Dyed Fabric and The Perfect Quality Fabric Will Enter into Next Process. Handled by Experienced and Powerful Bonding Factory, Coating Factory, Printing Factory Embossed Factory and So On. The Whole Process Will Be Tracked by Our 10 Years Experienced Quality Person.

5,Packing of Finished Fabric

Inspected by Experienced Person in Perfect Bright Room, Reject the Defective

Finished Fabric and the Perfect Quality Fabric Will Be Packed as Per Customer's

Instruction.

6,Fabric Be Loaded and Shipped

Handled by Experienced Person to Arrange The Shippment for Customers. Using Customer's Shipping Agent or Our Own Shipping Agent to Ship Out the Goods.

Our Contact